3 Ways to Prolong the Life of Your Grease Trap

Follow These Tips to Keep Your Restaurant or Business Running Smoothly

A grease trap is essential for any commercial kitchen, preventing fats, oils, and grease (FOG) from clogging sewer lines and causing costly plumbing issues. However, just having a grease trap isn’t enough—it needs to be properly maintained and used correctly to ensure it functions effectively. Here are three ways to extend the life of your grease trap and keep your kitchen running smoothly.

1. Do Not Skip Routine Maintenance

Grease traps fill up quickly, and once they reach capacity, they become less effective at keeping grease out of your plumbing system. Without regular cleanings, hardened grease buildup can lead to backups, unpleasant odors, and expensive repairs.

A good rule of thumb for grease trap maintenance in Central PA is to have it cleaned every 1-3 months, depending on your kitchen’s volume. The longer you wait, the more difficult and costly the service becomes. At John Kline Septic Services, we offer professional

grease trap pumping and

high-pressure jetting in Central PA to ensure your system stays clean and fully functional.

If you’ve gone longer than usual between cleanouts or you’re unsure when your pipes were last cleaned, we recommend scheduling a service that includes both grease trap pumping and high-pressure jetting. This removes all accumulated grease and clears blockages in the pipes leading away from your kitchen, preventing future issues.

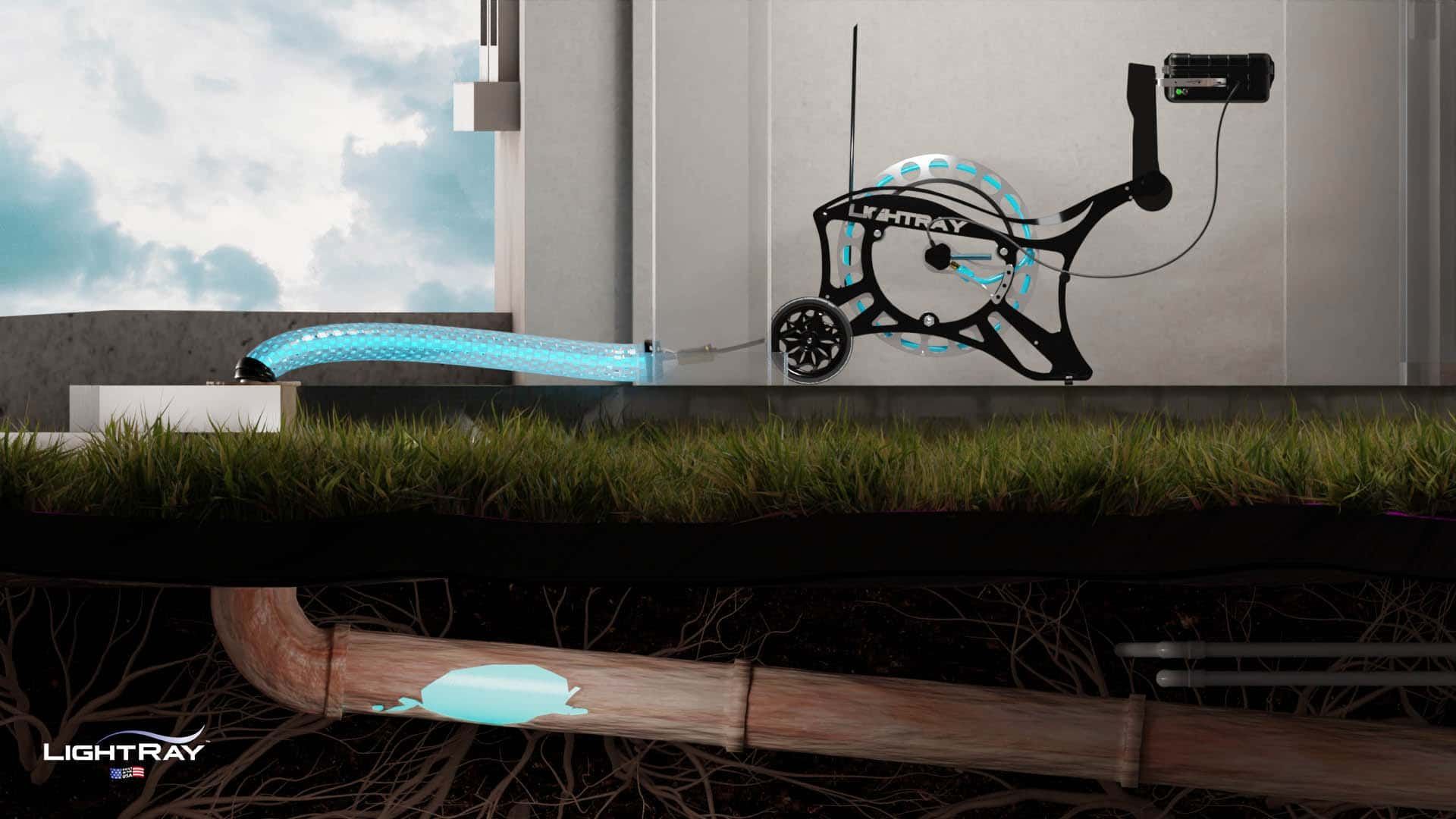

Grease trap replacement process - before and after

2. Make Sure Your Grease Trap Is the Right Size

If your grease trap is too small for your restaurant or business, it will fill up faster, requiring more frequent cleanings and increasing the risk of overflows and backups. The right size trap ensures efficient separation of grease and wastewater, reducing maintenance costs and preventing plumbing problems.

Another issue to watch for is improper installation. If your grease trap is installed incorrectly, it may not be separating grease effectively. A clear sign of a faulty installation is minimal grease accumulation in the trap, which means FOG is likely flowing straight into your pipes. If you suspect an issue,

call John Kline Septic Services for an inspection—we can check your setup and ensure it’s working properly.

3. Dispose of Food Waste and Grease in the Trash—Not Down the Drain

Even with a properly sized and maintained grease trap, your kitchen staff should follow best practices to reduce the amount of grease entering the system. Food scraps, oil, and grease should be scraped into the trash rather than washed down the sink. Additionally, make sure all food prep and dishwashing sinks are connected to the grease trap—this helps capture as much grease as possible before it reaches your pipes. Encouraging staff to follow proper disposal practices will significantly reduce the strain on your grease trap, extending its lifespan and reducing maintenance costs.

How Does a Grease Trap Work?

A grease trap is a device that intercepts FOG from wastewater before it reaches the sewer system. As wastewater flows through the trap, grease and oils rise to the top while heavier solids settle at the bottom. The remaining water then exits into the plumbing system, leaving the grease and solids behind for removal.

Grease traps and grease interceptors serve the same purpose but differ in size and installation. Smaller grease traps are often installed under sinks, while larger interceptors are placed underground or outside the building. Regardless of the type, regular maintenance is crucial to ensure proper function.

Keep Your Grease Trap and Plumbing System in Top Shape

At John Kline Septic Services, we specialize in grease trap pumping, septic pumping, and drain line jetting for restaurants and businesses in Lancaster, PA, and the surrounding Central PA region. Whether you need routine maintenance or a full cleanout with high-pressure jetting, we’re here to help.

Don’t wait for a grease trap emergency—schedule your service today and keep your kitchen running smoothly!